| Sign In | Join Free | My uabig.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My uabig.com |

|

Certification : ISO, UL, IPC, Reach

MOQ : 1

Payment Terms : T/T

Supply Ability : Post-soldering 700,000 points/day

Delivery Time : 5-30 days

Layer : 2 Layer

Material : Aly

Board Thickness : 0.5mm

Surface Finish : HASL

Pin Space : 0.2mm

Application : LED

2 Layer Flexible PCB Assembly for LED

♦ What is Flexible PCB Assembly?

Flexible PCB Assembly (Flex PCBA) is the process of mounting and soldering electronic components onto a flexible printed circuit board (Flex PCB)—a bendable, lightweight alternative to traditional rigid PCBs. These assemblies are used in applications where flexibility, space savings, or dynamic movement is required.

✔ Bendable & Lightweight – Can be folded, twisted, or shaped to fit tight spaces.

✔ High-Density Interconnects – Supports complex circuitry in compact designs.

✔ Durability – Resists vibration, shock, and mechanical stress better than rigid PCBs.

✔ Thin & Light – Ideal for wearable tech, medical devices, and aerospace.

♦ Flexible PCB Assembly Process?

| Type | Description | Applications |

|---|---|---|

| Single-Sided Flex PCBA | Components on one side. | Simple wearables, sensors. |

| Double-Sided Flex PCBA | Components on both sides. | Cameras, medical devices. |

| Multilayer Flex PCBA | 3+ conductive layers. | High-speed electronics (5G, aerospace). |

| Rigid-Flex PCBA | Combines rigid and flex sections. | Foldable phones, military systems. |

DQS Electronic Group is one of the leading EMS company in China, we provide PCB design, PCB manufacturing, PCB assembly service and testing. Welcome send us your Gerber file to get free quotation. Our email: sales@dqspcba.com

♦ Technical Parameters

| PCB Assembly Capability | |||||

|

Item |

Normal |

Special | |||

|

SMT Assembly |

PCB(used for SMT) specification | Length and Width( L* W) | Minimum | L≥3mm, W≥3mm | L<2mm |

| Maximum | L≤800mm, W≤460mm | L > 1200mm, W>500mm | |||

| Thickness( T) | Thinnest | 0.2mm | T<0.1mm | ||

| Thickest | 4 mm | T>4.5mm | |||

|

SMT components specification | Outline Dimension | Min size | 0201(0.6mm*0.3mm) | 01005(0.3mm*0.2mm) | |

| Max size | 200 * 125 | 200 * 125 | |||

| component thickness | T≤15mm | 6.5mm<T≤15mm | |||

| QFP,SOP,SOJ (multi pins) | Min pin space | 0.4mm | 0.3mm≤Pitch<0.4mm | ||

| CSP/ BGA | Min ball space | 0.5mm | 0.3mm≤Pitch<0.5mm | ||

|

DIP Assembly |

PCB specification |

Length and Width( L* W) | Minimum | L≥50mm, W≥30mm | L<50mm |

| Maximum | L≤1200mm, W≤450mm | L≥1200mm, W≥500mm | |||

| Thickness( T) | Thinnest | 0.8mm | T<0.8mm | ||

| Thickest | 3.5mm | T>2mm | |||

|  |  |  |

|  |  |  |

2. Quality Guaranteed:

3. Premium Service:

|

|

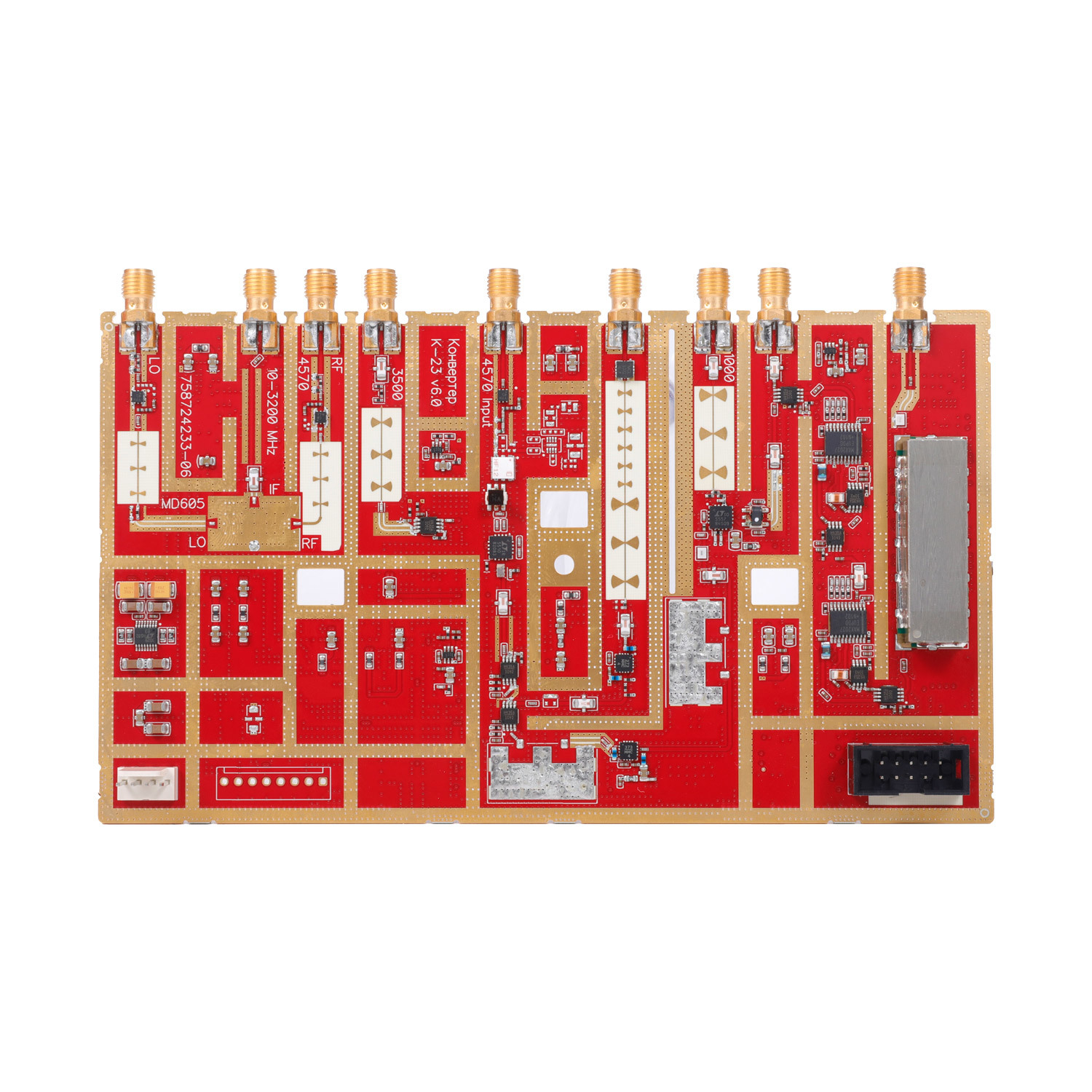

2 Layer Flexible Multilayer PCB Assembly For digital LED Images |